Blending Liquid Rubber & Plastic: Poly-Optic® Series

Poly-Optic 14-SeriesCasting Resins are two-part, room temperature curing, polyurethane systems that result in water-clear castings. They can be colored with PolyColor Dyes to achieve transparent, colored castings.

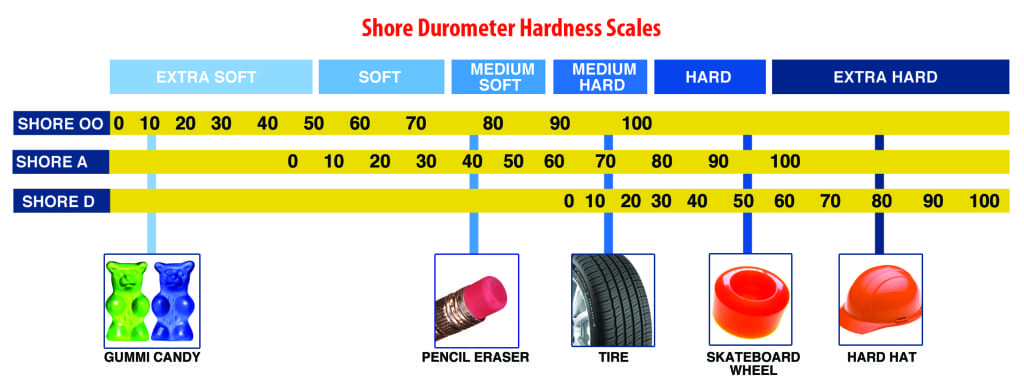

There are six individual product options within this series, most of which result in a rigid, Shore D80-D85 plastic. One option; however, is a firm rubber that cures to a Shore A70 hardness. As points of reference, Shore D80-D85 is comparable to the hardness of a hard hat, while Shore A70 is similar to that of a car tire [more examples of Shore hardness are below].

Blending Poly-Optic Products to Achieve Varying Hardness

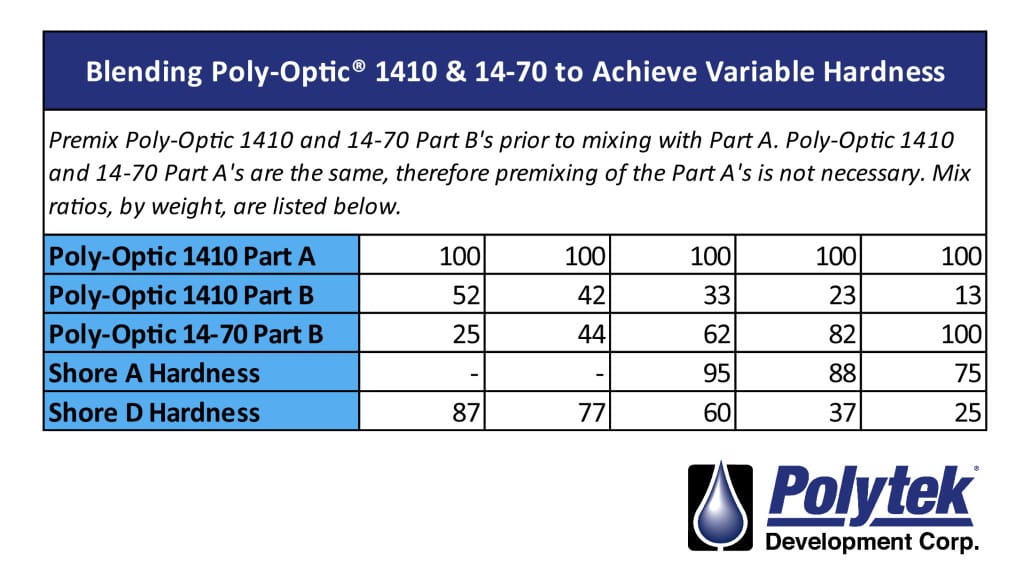

If you require a clear polyurethane plastic that has a hardness between Shore A70 and Shore D80, Poly-Optic 1410 (a hard, Shore A80 plastic) and Poly-Optic 14-70 (a firm, A70 rubber) can be blended at different ratios to achieve varying hardness.

[Samples of blended Poly-Optic cast in a slate tile mold:

25% 1410/75% 14-70, 75% 1410/25% 14-70, 50% of each]

In the table below, you will find what ratios (by weight) these two Poly-Optic products should be mixed at to achieve varying Shore hardness.