Millwork & Ornamentation

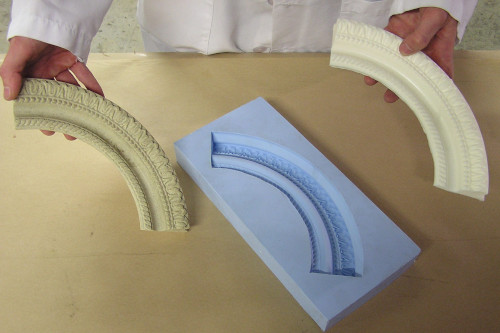

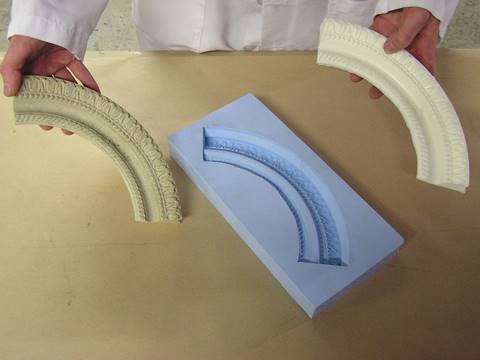

Produce decorative millwork and architectural décor elements with Polytek® mold making and casting materials

Polytek® casting materials, including polyurethane foams and polyurethane resins, are used to cast a wide variety of rigid and semi-rigid decorative millwork and architectural decor elements that can be used in both interior and exterior environments (parts must be painted for use outdoors).

Polytek pourable and brushable polyurethane and silicone rubbers can be used to make high-performance molds to cast finished parts.

Select a product line below to learn more:

Polyurethane Materials

Polyurethane Plastics: Rigid & Semi-Rigid

Poly-PlastiFlex is a slightly flexible polyurethane plastic that is popular for producing decorative trim molding and millwork.

A variety of other polyurethane plastics are also available for producing rigid parts.

Polyurethane Foam

PolyFoam rigid polyurethane foams can be used to cast finished parts of varying densities. Silicone molds are typically sprayed with a fast-curing primer prior to casting the foam so that the part is pre-primed when removed from the mold.

Polyurethane Rubber

Polytek® polyurethane mold rubbers are most often used when casting reproductions in plaster and concrete and limited resin casting. Polyurethane molds are economical and long-lasting.

Silicone Materials

Silicone Rubber

Polytek® silicone mold rubbers are most often used when making molds for resin or foam casting - release agents are generally not needed for either process, which is why they are sometimes preferred over polyurethane mold rubbers. For resin castings that need to be painted after casting, silicone mold rubbers are recommended.

Application Examples