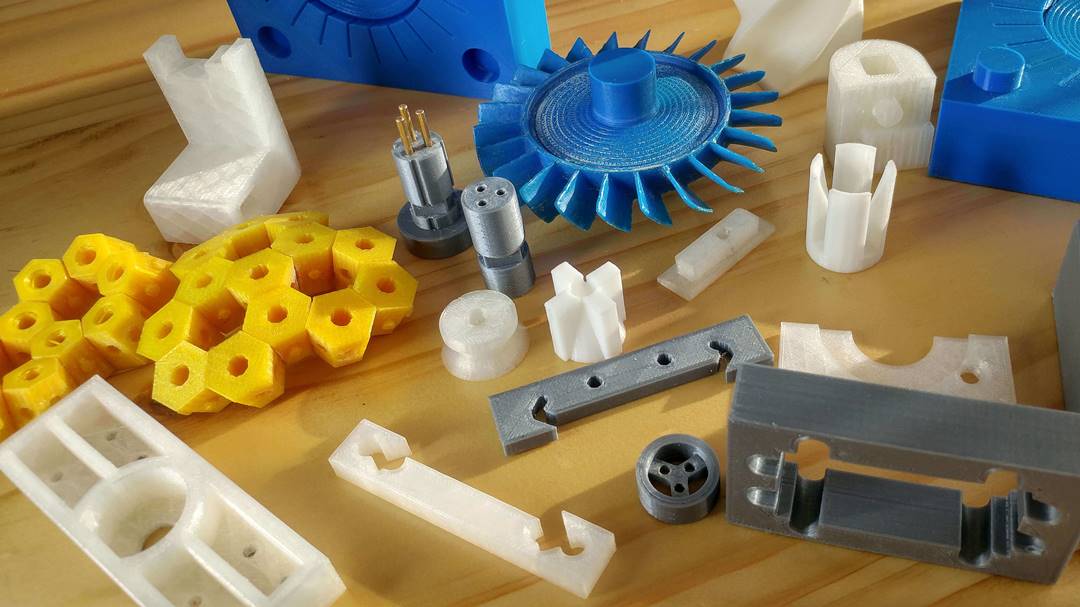

Prototyping & Short-Run Production

Create custom prototypes and parts with Polytek® mold making, casting, & coating

Polytek's wide range of material solutions can be used by engineers, designers, and developers to produce prototypes and parts that meet their unique specifications.

Create rigid and flexible molds or parts using silicone, polyurethane, epoxy, or use in conjunction with 3D printing processes to achieve a working prototype model.

From concept, to prototype, to short-run production, Polytek materials are versatile tools that can help you every step of the way.

Select a product line below to learn more:

Polyurethane Materials

Polyurethane Plastic: Rigid & Semi-Rigid

Use Polytek® polyurethane casting resins to create a number of finished objects and décor. From fast-setting resins to water-clear options, almost any color, size, shape, weight and appearance can be achieved by using these systems.

Polyurethane Foam

Polyurethane foams is often used to produce lightweight objects, props, architectural elements and décor. They can be used to make finished parts, but are also used to back all other casting materials, such as polyurethane plastic.

Polyurethane Rubber

Polytek® manufactures a high-quality line of two-part, room-temperature curing (RTV) polyurethane rubbers that can be poured, brushed or sprayed to make molds or flexible parts. Polyurethane rubbers are most often used to make molds for casting wax, plaster and concrete.

Silicone Materials

Silicone Rubber

Polytek® silicone mold rubbers are most often used when making molds for resin or foam casting. Release agents are generally not needed for either process, which is why they are sometimes preferred over polyurethane mold rubbers.

Silicone Foam

PlatSil® SiliFoam is a platinum-cured silicone foam with a 15 lb/ft³ density. Often used in conjunction with PlatSil® Gel Silicone Rubbers to create prosthetic appliances and props.

Epoxy Materials

Laminating Epoxies

PolyPoxy® Laminating Epoxies are low viscosity, room temperature curing (RTV) systems formulated for general purpose and high-temperature fabrication applications.

Surface Coat Epoxies

PolyPoxy® Surface Coat Epoxies are thixotropic, room temperature curing (RTV) systems formulated for the fabrication of general purpose or heat-resistant laminated tools, including dies, foundry patterns, core boxes, and router, trim and inspection fixtures.

Casting Epoxies

PolyPoxy® Casting Epoxies are aluminum-filled, heat-resistant, room temperature curing (RTV) systems that are typically used for heat-resistant vacuum form tools, injection and compression molds, RTM and RIM molds, and matched dies.

Epoxy Adhesives

PolyPoxy® Epoxy Adhesives are two-component, room-temperature curing (RTV) systems designed to be used as general-purpose adhesives as well as a bonding adhesive for TekBoard™ Tooling & Modeling Board.

Application Examples