Use PlatSil® Series liquid silicone rubbers to manufacture high-performance silicone molds and silicone parts.

PlatSil® rubbers are platinum-cured (also known as addition-cure), room temperature-curing silicones that cure to flexible, high-strength rubbers. PlatSil® molds offer excellent release properties and release agent is not necessary when casting most materials. Compared to tin-cured silicone rubbers, platinum-cured silicones exhibit long library life and low shrinkage on cure.

Silicone rubber is an excellent mold material, but select silicone products are also widely used as a casting medium in applications including medical modeling, special effects, and orthotics.

Several of our PlatSil Silicone Gels have been independently certified as skin safe. This means that these products comply with the requirements of applicable sections U.S. Federal Hazardous Substance Act (FHSA) Regulations (16 CFR 1500), LHAMA (16 CFR 1500.14), ASTM D4236, Sections 201(s) and 409 of the Federal Food, Drug, and Cosmetic Act and requirements for Toxicology Risk Assessments.

View our new Medical Modeling and Simulation brochure for more information.

Technical Data Bulletin for our standard line of PlatSil Silicone Gels

Technical Data Bulletin for our PlatSil Silicone Gels including Dry Versions

Select a product line below to learn more or continue to scroll to review product line features and common applications:

Product Line Features

- Type: Platinum-cured (addition-cured) silicone rubber

- Room-temperature curing (RTV)

- A wide range of durometers

- 1:1 and 1:10 mix ratios

- High temperature resistance (up to 450°F)

- Low and high viscosity options

- Low shrinkage

- Translucent options

- Product options that comply with 21 CFR 177.2600 for repeated use food contact surfaces

- Skin-safe options in the PlatSil® Gel Series

- Accelerators, retarders, thickeners, pigments and other accessories that adjust the liquid and cured properties of the silicone

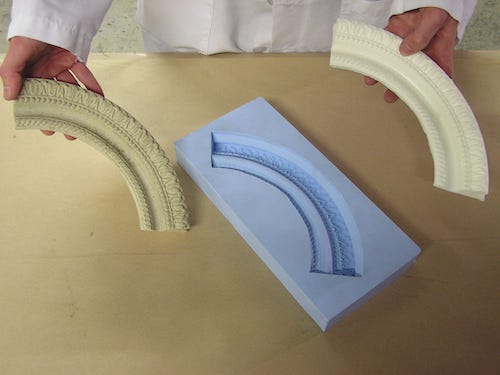

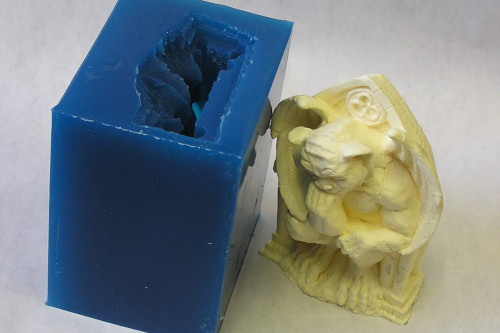

- Silicone molds can be used to cast a variety of materials, including: polyurethane, polyester and epoxy resin, polyurethane foam, low melting metals, concrete, plaster, wax, platinum-cured silicone, and more

Common Applications

Application Examples