Use Polytek® polyurethane plastics to make parts and objects of almost any color, size, shape and weight.

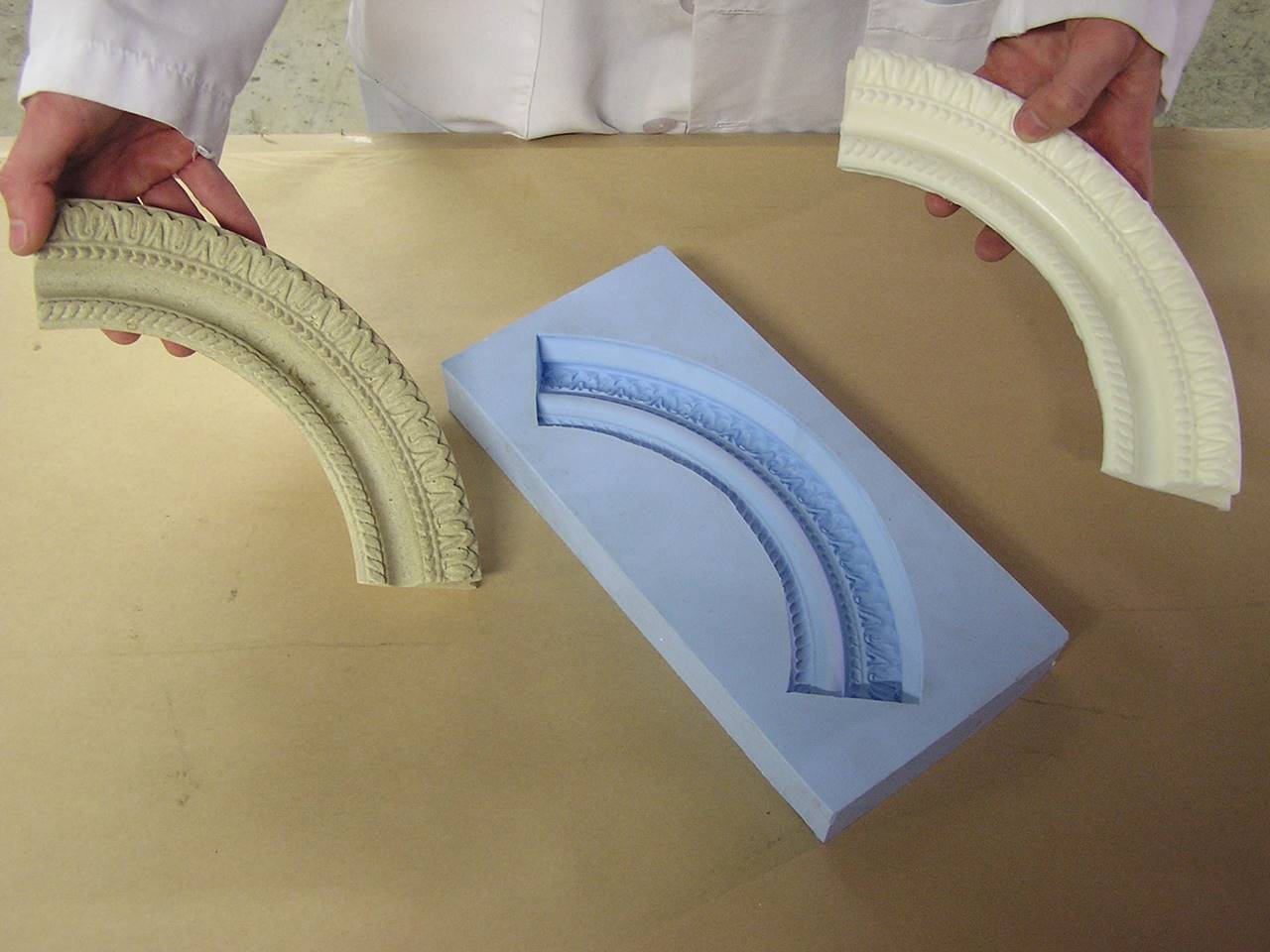

Polytek's two-part, room-temperature curing polyurethane plastics are available in varieties that can be poured, brushed or sprayed to create castings with unlimited versatility.

These plastics are separated into five different series, highlighted below. From super low-viscosity, fast-setting resins to water-clear options, almost any color, size, shape, weight and appearance can be achieved by using these systems. Utilize available accessories to help achieve the desired look and feel.

Select a product line below to learn more or continue to scroll to review product line features and common applications:

Product Line Features

- Type: Two-part polyurethane plastics

- Room temperature curing (RTV)

- Rigid and semi-rigid options

- Filled & unfilled systems

- Water-clear options

- Polyurethane plastics can be cast in silicone rubber molds without any release agent, but require a release agent when cast in polyurethane rubber molds.

Common Applications

Application Examples